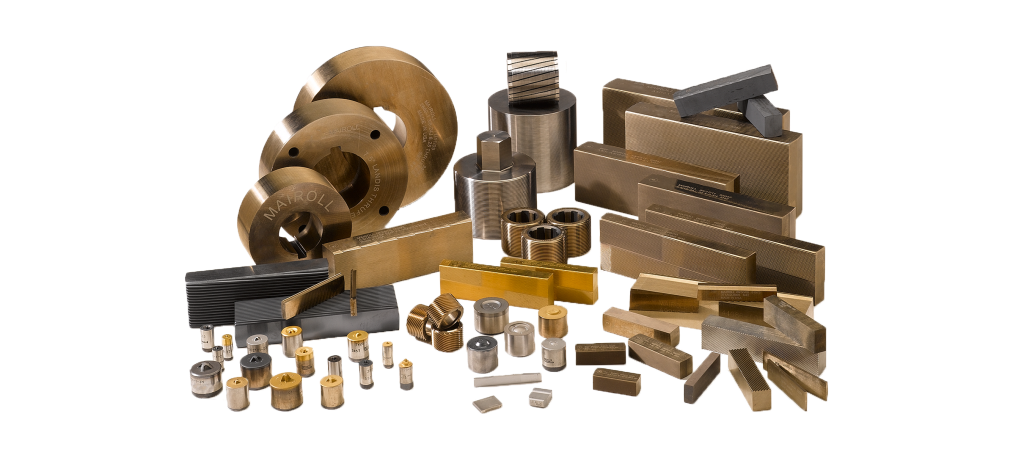

Flat dies

Howmet Fastening Systems’ flat dies feature Super M-42 material, which is vacuum heat-treated and tempered for maximum toughness and durability. This provides the longest possible thread rolling life, resulting in reduced set-ups, fewer dies to purchase and significant cost-savings. All dies are synchronized and center-matched to reduce variability in set-ups. Howmet Fastening Systems manufactures all standard, controlled major and modified thread forms to meet customer needs. Custom form requirements also can be met. Precise and accurate thread forms assure the customer high-quality parts that meet or exceed today’s stringent aerospace and commercial quality standards. Dies in unified and metric sizes are available in the following configurations: boltmaker single and split face, controlled major forms, custom designs, fillet rolls, groove dies, knurl, special forms and standard duplex.