We’re a company of innovators and makers. We are transforming the future of flying and driving with high-performance engineered solutions that are paired with advanced manufacturing expertise.

We help make quieter, more fuel-efficient engines for airplanes and gas turbines. Our market-leading aluminum wheels help trucks save fuel and reduce maintenance while rolling in style. Our customers’ products stay connected and secure with our high-tech fastening systems.

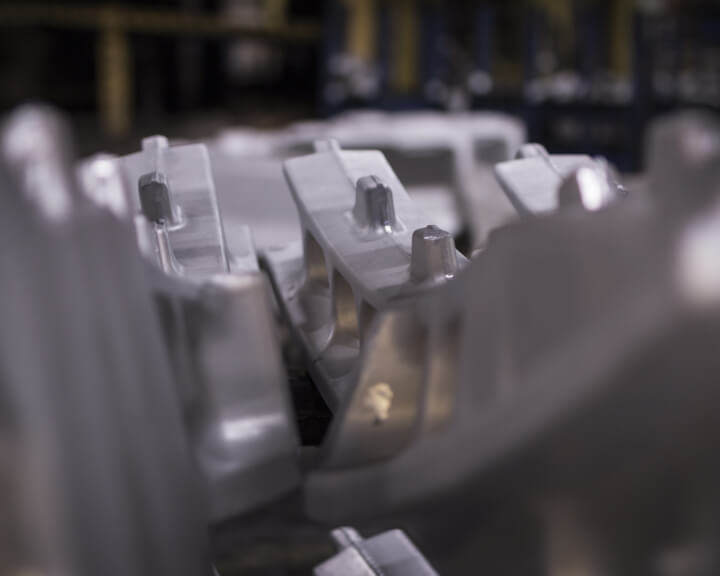

Engine Products

We are a world-class producer of aero engine and industrial gas turbine components, including airfoils, rings, disks and forgings. We excel in vacuum-melted superalloys, machining, performance coatings and hot isostatic pressing for high-performance parts that enable the next generation of quieter, more fuel-efficient aerospace engines and cleaner power generation.

Engineered Structures

We are a world-class producer of titanium aero ingots and mill products – and a leader in highly engineered, multi-material structures for aircraft. We combine metallurgical expertise in titanium and aluminum with vertically integrated manufacturing capabilities – including casting, forging, extruding, hot forming and machining – to produce innovative products for the aerospace and defense markets.

Fastening Systems

We hold the number one global position in aerospace fastening systems, and we’re the North American leader in commercial transportation fasteners. Our high-tech, multi-material fastening systems are found nose to tail on aircraft and aerospace engines. Our products are also critical components of industrial gas turbines, automobiles, commercial transportation vehicles, and construction and industrial equipment.

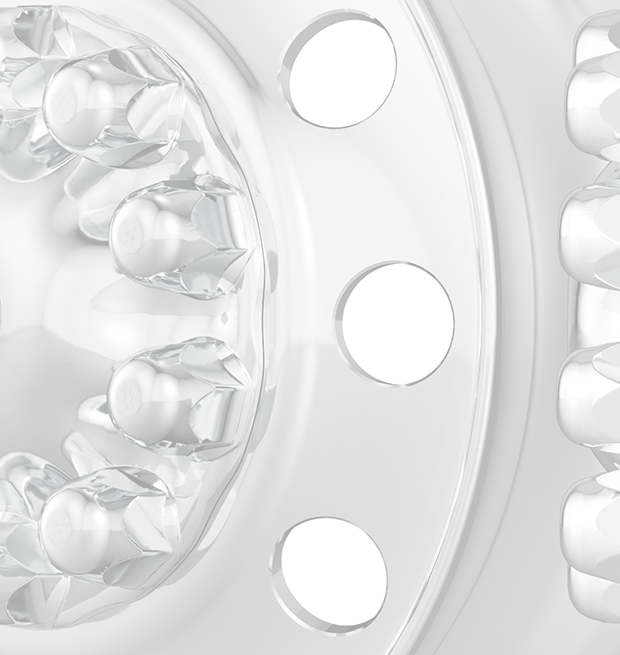

Forged Wheels

We invented the first forged aluminum truck wheel in 1948 – and by doing so, we created an entire industry. Seven decades later, we’re proud to be the number one global market leader in the forged, aluminum heavy-duty truck wheel market. We’ve helped customers around the world to increase payload while saving fuel and reducing maintenance by switching out heavy steel wheels for lightweight aluminum.