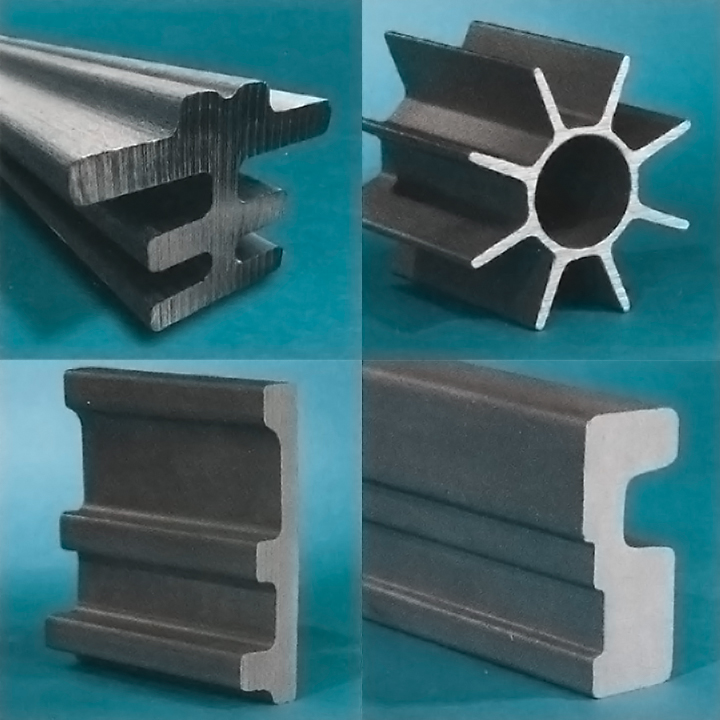

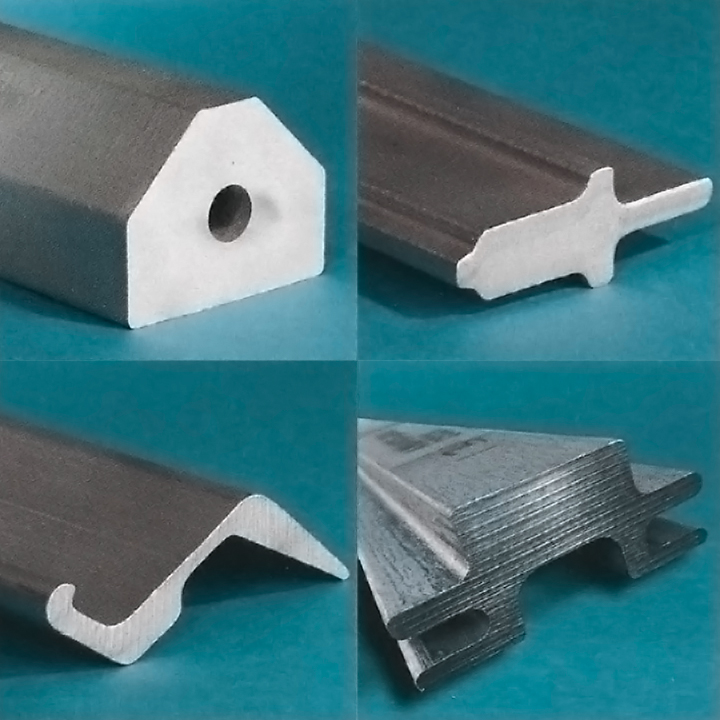

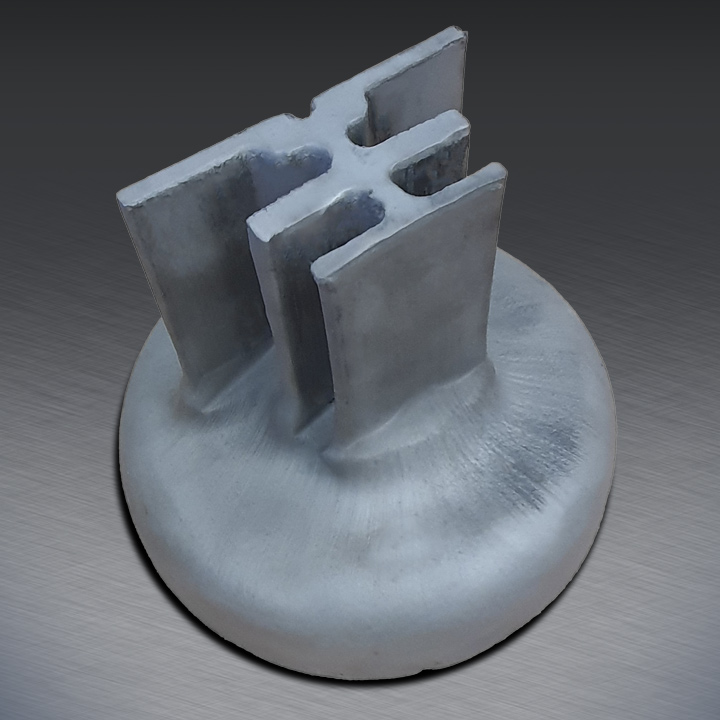

We are experts in complex metal shapes.

Howmet Aerospace Extrusions (formerly RTI Extrusions) currently produces over 16,000 extruded solid & hollow profiles a year in a wide range of alloy steels, stainless steels and titanium grades. Our plant in Low Moor, UK, utilizes a 1,250 Ton Extrusion Press.

We supply to 20 countries in Europe, Africa, Central and North America & Asia. Our extrusions are used in over 30 different industries and markets including:

Aerospace

Agriculture

Architectural

Automotive

Bearings

Construction

Defense

Electronics

Food

Further processing

General engineering

Hire work

Marine

Material handling

Medical

Metals

Paper & pulp

Petrochemical

Power generation

Press brake tooling

Pumps & valves

Railway

Textile machinery

Tools & cutting

Capabilities

Maximum Section Size

Profile to fit within a 152mm (6 inch) diameter circle with capability to go up to 343mm (13-5 inch) at our Houston Facility.

Weight per Extrusion: Up to 150kg (330 lbs)

Extrusions can be supplied in: Random, typical 5 to 8m (16 to 26ft) or Fixed Lengths

Minimum order quantity: As low as 250kg (550 lbs)

Cold Draw

Cold Drawing improves surface finish, material properties and can reduce dimensional tolerances to +0-0.25mm (=0-0.010 in.).

40 Ton Cold Draw Bench with associated Tag forming & Die renovation equipment

Materials Drawn: Carbon Steels, Alloy Steels, Stainless Steels

Minimum Size: 12.9 x 8.9mm (0.51 x 0.35 in.)

Maximum Size: to fit within diameter 100mm (4 in.)

Materials extruded

Titanium Alloys

Ti 6Al 4V AMS4935, DMD780-24, MTS1160,

MIL-T-81556, Ti 6-6-2 MIL-T- 81556, Ti-2-5Cu

MTS1021, Ti 5Al4V, Ti 6-2 -4-6, Ti 5-5-5-3

General Carbon, & Alloy Steels

1018, 817M40, 080M30, ST52-3

Armour Steel

4130, 4140, TL2350, IT140 to Def Stan 95-23

Austenitic Stainless Steels

304 L, 316L, 321, 347, XM19

Martensitic Stainless Steels

410, Jethete M152, Greek Ascalloy AMS5616

Duplex Stainless Steels

UNS31803, UNS32550

Precipitation Hardening Steels

17/4PH, 15/5PH

Nickel Alloys

Nickel 201, Alloy 600, Monel 400

Dimensional limits

Title

| Maximum cross sectional area | 6300mm sq | 9-765 in sq |

| Minimum web thickness | 4.0mm | 0.160 in |

| Minimum internal corner radius | 1-5mm | 0.060 in |

| Minimum external corner radius | 0.8mm | 0.030 in |

| Angular tolerance | +/- 2 Deg | |

| Twist/straightness/bow | 1 in 500 |

Dimensional Tolerances

Millimeters

| 4.5-2499 | +/-0-4 |

| 25 to 4999 | +/-0-5 |

| 50 to 74-99 | +/- 065 |

| 75 to 99-99 | +/- 075 |

| 100 to max | +/-1.0 |

Inches

| 0.180-0.99 | +/- 0.016 |

| 100-1.99 | +/- 0.020 |

| 2.00-2.99 | +/- 0.025 |

| 3-00-3-99 | +/- 0.030 |

| 4.00 to max | +/- 0.040 |

Wall thickness tolerances

For hollows

| Up to 6.24mm | +/-10% | Up to 0.25 in | +/- 10% |

| 6.25 to12-49mm | +/-7-5% | 0.26 to 0-49 in | +/-7-5% |

| 12-5mm to max | +/-5% | 0-50 in to max | +/-5% |

Learn more about our extrusion products and capabilities.