Huck-Clinch® Blind Rivets

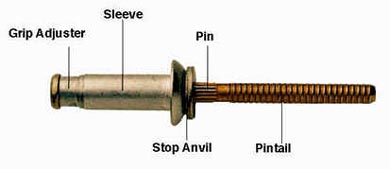

Huck-Clinch® blind rivets are aerospace fasteners precisely produced to the requirements of MIL-R-7885 and NAS1686 procurement standards. Huck-Clinch® blind rivets are available in standard and oversize diameters. These blind rivets are constructed with alloy steel or CRES spindles. The Huck-Clinch® blind rivet meets the sheet take-up and hole-fill requirements of military and industry specifications. The rivet is a four-piece assembly consisting of the components shown in the following illustration.

Component descriptions

Grip adjuster: The grip adjuster is the part of the fastener that forms the blind head and generates clamp load during installation.

Sleeve: The sleeve is the body of the fastener that comes in contact with the fastened material.

Stop anvil: The stop anvil is part of the installation tool, which allows for all diameters of rivets to be installed with a single nose assembly. Its function is to stop spindle motion during installation to provide for a flush spindle break.

Pin: The pin, or spindle, is the core of the fastener and is designed to perform the functions of blind head formation, sheet take-up, hole-fill and lock forming. The pintail is that portion of the spindle that the installation tool grips and pulls to install the fastener.

Huck-Clinch® blind rivet key performance features

Hole-filling capabilities: During spindle-lock formation, the Huck-Clinch® blind rivet provides hole-fill capabilities at both ends of the installed fastener.

Sheet take-up capabilities: The grip adjuster on the Huck-Clinch® blind rivet maintains a consistent blind side pressure during installation to ensure sheet take-up.

High retained clamp force: Clamp force is generated and maintained throughout the installation process by the grip adjuster. It adjusts itself to grip conditions by bulbing to maintain consistent clamp load.

Enhanced fatigue performance: Because of the hole-fill capability and high-clamp performance, the Huck-Clinch® rivet provides enhanced fatigue performance.

Vibration resistant: The Huck-Clinch® fastener is resistant to vibration due to its hole-fill and high-clamp capabilities. Additionally, the solid circle internal lock provides a tight fit between pin and sleeve to resist vibratory conditions.

Flush pin break: The stop anvil used as part of the fastener assembly is designed to eliminate spindle motion during installation to result in a flush pin break. Shaving is not required to achieve aerodynamic surface quality.

Internal solid circle lock, high spindle retention: The positive spindle lock is created by extruding sleeve material into a lock groove on the pin during installation. The lock results in a high spindle-retention load.

Capable of rivet shaving: The Huck-Clinch® blind rivet is designed to form an internal “solid circle” mechanical lock during the installation process. This permits aerodynamic rivet shaving on contoured surfaces without damage to the mechanical lock or performance of the installed fastener.

Moisture and crevice corrosion resistant: The Huck-Clinch® blind rivet is designed with interference fit between spindle and sleeve, which prevents moisture from entering the fastener from the installed side. With the hole-fill capabilities of the rivet sleeve, further joint sealing is achieved.

Enhanced joint allowables: Joint allowables for the Huck-Clinch® blind rivet are included in the MMPDS Handbook.

Minimal rework: Field experience by our customers has shown that the Huck-Clinch® blind rivet system has unusually low rework incidence.